- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 5 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

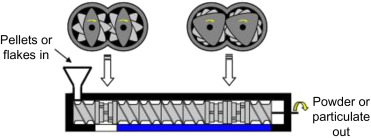

Solid-state shear pulverization (SSSP) is a process that uses a modified TSE with cooling zones to maintain the polymer in the solid state during processing. High shear and compressive forces result in repeated fragmentation and fusion of polymer in the solid state producing excellent mixing and dispersion of polymer blends.

SSSP extrusion schematic is shown in Fig. 1. The SSSP setup is a modified TSE from Berstorff with the ability to cool the barrel below room temperature. Pulverization screw designs differ from conventional twin-screw extrusion due to the use of trilobe rather than bilobe screw elements along a portion of the screw.

Fig. 1

Fig. 2 shows a patented SSSP extrusion setup. This setup uses a rotating conical meshing screw design to form fine powder by applying normal and shear forces on the polymeric material